1

What is Bale Stacking?

Staple fibers

are low density materials and need to be compressed in bales form to transport

from one place to other. Fibers are compressed to bales of a specific length,

width, height and density in ginning factory and then transported to spinning

mills. Spinning mills buy cotton bales according to their annual requirement

during the season and store them in warehouses and godowns. These bales are

stacked on one another in godowns and dispatched during the whole year

according to requirements. This is called Bale Stacking.

2

Bale Stacking Stability

At most sites,

bales are held in a warehouse or similar storage area, waiting for process or

dispatch. The main safety objective in

the storage area is to maintain safe and stable stacks, so bales do not fall.

Instability can

happen in two ways:

¶

stacks may be unstable from

the outset because of poor stacking techniques.

¶

stacks may have been stable

originally but have become unstable; possible causes for this could be

disturbance as adjacent bales are stacked or de-stacked, or disturbance if

struck by a lift truck, slippage of bales.

Safe working

procedures for stacking and de-stacking should be drawn up and agreed with all

appropriate personnel. These procedures

should consider:

¶

the limitations of storage

area such as the floor space and height available.

¶

the physical properties of

the various types of bales.

¶

the type of lifting and

handling equipment to be used.

3

General Pointers to Safe

Storage

¶

Keep gangways/walkways

clear within the storage area and between stacks, to allow safe movement of

lifting and handling equipment.

¶

The storage space reserved

for bales should have adequate space to allow safe movement of equipment and

bales in the area, maintaining clear gangways.

¶

Floor surfaces should be

firm and level.

¶

Floors should not be

overloaded.

¶

Stacking in a pyramid

fashion and using binder bales can help to keep stacks stable.

¶

Store damaged or

doubtful-looking bales separately, not in the bulk of a stack.

¶

Inspect stacks at least

weekly and keep a record of the inspections and any resulting action.

¶

Make sure timber pallets

are in good condition if they are used.

¶

Make sure personal

protective equipment worn during handling, packing and unpacking of bales is

adequate.

¶

Introduce a safe system of

work and procedures for bale handling, stacking and de-stacking.

¶

Provide training in bale

handling and handling equipment.

To minimize climbing

on stacks, attach identification tickets to bales where they can be read easily

by a person standing at floor level.

4

Bale Stacking at JK

Spinning Mills

In this

assignment we studied, bale storage and stacking techniques at JK Spinning

Mills, 29-km Sheikhupura road, Faisalabad.

J.K Spinning

Mill consumes almost 100,000 cotton bales per year. There are total 43 godowns

in J.K Spinning Mill; having storage for up to 94,600 bales. These 43 godowns

are used by all the tree units of J.K Spinning Mill. The bales are carried in the godowns through

lifter.

All the bales

are not of same specifications. JK Spinning Mills use following types of cotton

bales;

|

Bale type

|

Length (m)

|

Height (m)

|

Width (m)

|

Weight (kg)

|

Density (kg/m3)

|

|

Pakistani

|

1.1176

|

0.4826

|

0.9652

|

159

|

305.41

|

|

Indian

|

0.7874

|

0.5320

|

0.9827

|

161

|

391.10

|

|

W. African

|

1.3716

|

0.5588

|

0.8382

|

225

|

350.24

|

4.1

Godowns Dimension and

Capacity

Godown dimension

(L x W x H) = 1200” x 480” x 216” = 30.5m x 12.20m x 5.49m

Total volume of

godown = 2,042.83m3

4.2

Bale Stacking

Three types of bales are used in

JK Spinning Mills with each having different dimensions. So, out of 43 godowns,

24 are used for Pakistani cotton bales, 11 for Indian cotton bales and 8 for

West African cotton bales.

Stacking of

Pakistani bales in 24 godowns is as;

Length wise 25

bales along the length of godown, width-wise 8 bales along the width of godown

and 11 bales from floor to roof along the height of godown. Total bales in a

godown are;

No. of bales in

godown = 25 x 8 x 11 = 2,200

So volume

covered by bales in a godown is as;

(25 x 1.1176) x

(8 x 0.9652) x (11 x 0.4826) = 1,145.28m3

Estimated bales

according to area with empty space allowance for lifter are;

Estimated no. of

bales = 26 x 10 x 10 = 2600

Stacking

of Indian bales in 11 godowns is as;

Length wise 32

bales along the length of godown, width-wise 7 bales along the width of godown

and 10 bales from floor to roof along the height of godown. Total bales in a

godown are;

No. of bales in

godown = 32 x 7 x 10 = 2,240

So volume

covered by bales in a godown is as;

(32 x 0.7874) x

(7 x 0.9827) x (10 x 0.5320) = 922m3

Estimated bales

according to area with empty space allowance for lifter are;

Estimated no. of

bales = 34 x 8 x 10 = 2720

Stacking of

West African Bales in 8 godowns is as;

Length wise 20

bales along the length of godown, width-wise 12 bales along the width of godown

and 12 bales from floor to roof along the height of godown. Total bales in a

godown are;

No. of bales in

godown = 20 x 12 x 9 = 2,160

So volume

covered by bales in a godown is as;

(20 x 1.3716) x

(12 x 0.8382) x (9 x 0.5588) = 1,388m3

Estimated bales

according to area with empty space allowance for lifter are;

Estimated no. of

bales = 21 x 13 x 9 = 2,457

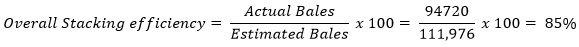

Total

bales stored at a time = 52,800 + 24,640 + 17,280 = 94,720

Estimated

total bales = 62,400 + 29,920 + 19,656 = 111,976

5

Conclusion

According

to standards, bales stacking efficiency should be in range of 80 – 90%. JK

Spinning Mills have 85% efficiency in this regard, so they are good in their

bale stacking plans. Bale stacking plan should utilize as maximum as possible

area of godowns.

No comments:

Post a Comment